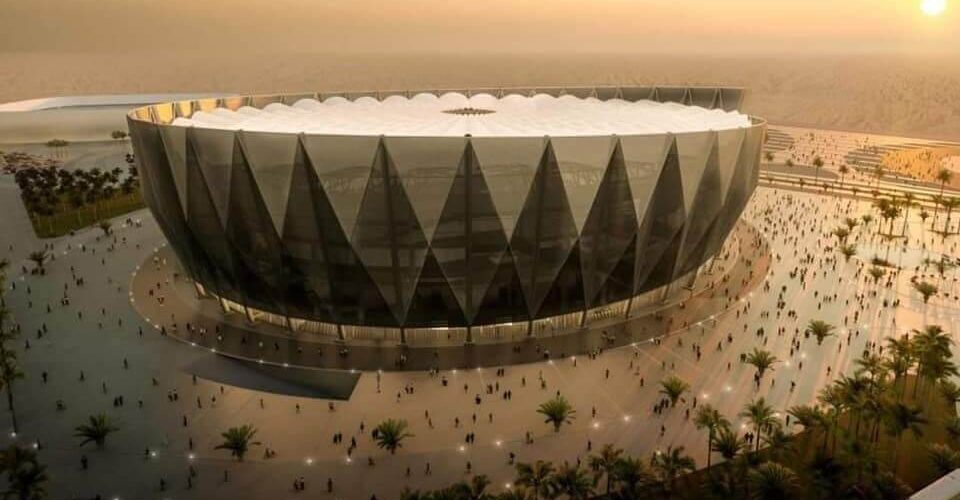

Precision Engineering for Performance: MODSTEEL’s Stadium Bearing Project in Egypt

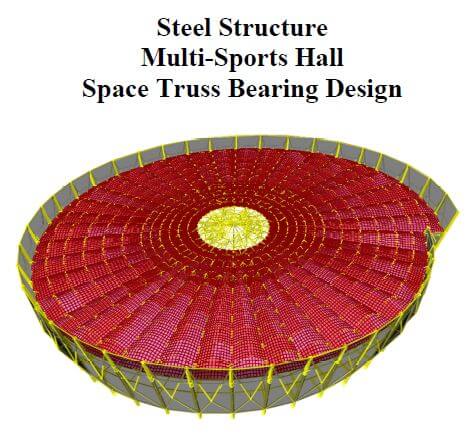

MODSTEEL recently completed a critical bearing and design calculation project for a stadium in Egypt, focusing on precision, durability, and engineering excellence. Our team developed customized bearing solutions tailored to meet the structural demands of a large sports venue, ensuring long-term stability, load-bearing capacity, and high resistance to dynamic forces.

Expert Engineering and Design Calculations

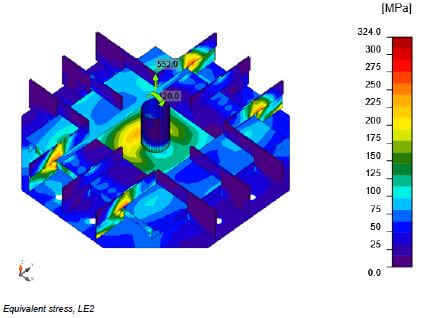

Our engineering team worked from initial planning to final installation, conducting extensive calculations to ensure the stadium bearings met the required load specifications, including support for both static and dynamic forces. We implemented uplift calculations to account for potential lateral forces and wind uplift pressures, which are essential considerations for large stadium structures. This process ensured the stability of the entire structure while protecting its integrity and longevity. With our experience in large-scale construction projects, MODSTEEL provided solutions that combine precision and reliability, giving our client full confidence in the results.

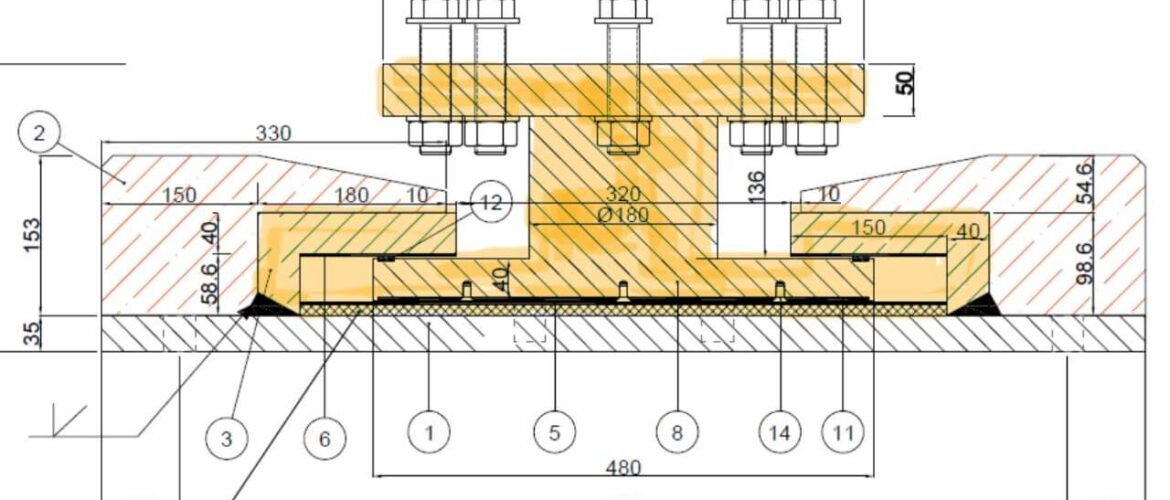

Advanced PTFE Teflon Bearings for Superior Performance

To address high friction and load requirements, MODSTEEL utilized advanced PTFE (Teflon) bearings in the stadium’s structural supports. These bearings are specially designed with PTFE layers, which provide exceptional load capacity, low friction, and long-term wear resistance. The Teflon surface enhances flexibility and allows for smooth movement, which reduces structural stress and allows the stadium to withstand heavy loads and temperature fluctuations. This technology is ideal for stadiums, where constant vibrations and movement demand high-performance bearings that can endure over time.

Compliance with International Bearing Standards

MODSTEEL adhered to international bearing standards, including AASHTO and EN 1337, ensuring that our design met global benchmarks for quality, safety, and durability. By following these standards, we guaranteed that each bearing installation could withstand the complex forces present in large venues, including vibration, seismic activity, and extreme weather conditions. These standards also allowed us to maintain a high level of precision and durability in the bearings, giving the client peace of mind that the structure will perform reliably over time.

Reliable Uplift Resistance for Structural Integrity

One of the core elements in our design was uplift resistance, a crucial aspect for any stadium structure. By conducting extensive calculations, MODSTEEL ensured that the bearings could resist forces pulling upward on the structure, such as strong wind forces and crowd movement. This attention to uplift protection enables the stadium to remain structurally sound during peak activity, safeguarding both the structure and its occupants.

Furthermore MODSTEEL’s work on the Egypt Stadium bearing and design project highlights our expertise in high-stakes engineering solutions. With advanced PTFE Teflon technology, compliance with strict international standards, and robust uplift resistance, our solutions deliver unmatched reliability, functionality, and long-term durability for large-scale structures.